French manufacturer / Plastic films, technical lay-flat tubing and polyethylene bags

French manufacturer / Plastic films, technical lay-flat tubing and polyethylene bags

You can trust our 60 years experience in plastic processing

for the development of your industrial packaging.

We transform polyethylene which is 100% recyclable and which can be customised and treated to your requirements.

We use virgin raw materials as well as post-industrial or post-consumer recycled materials.

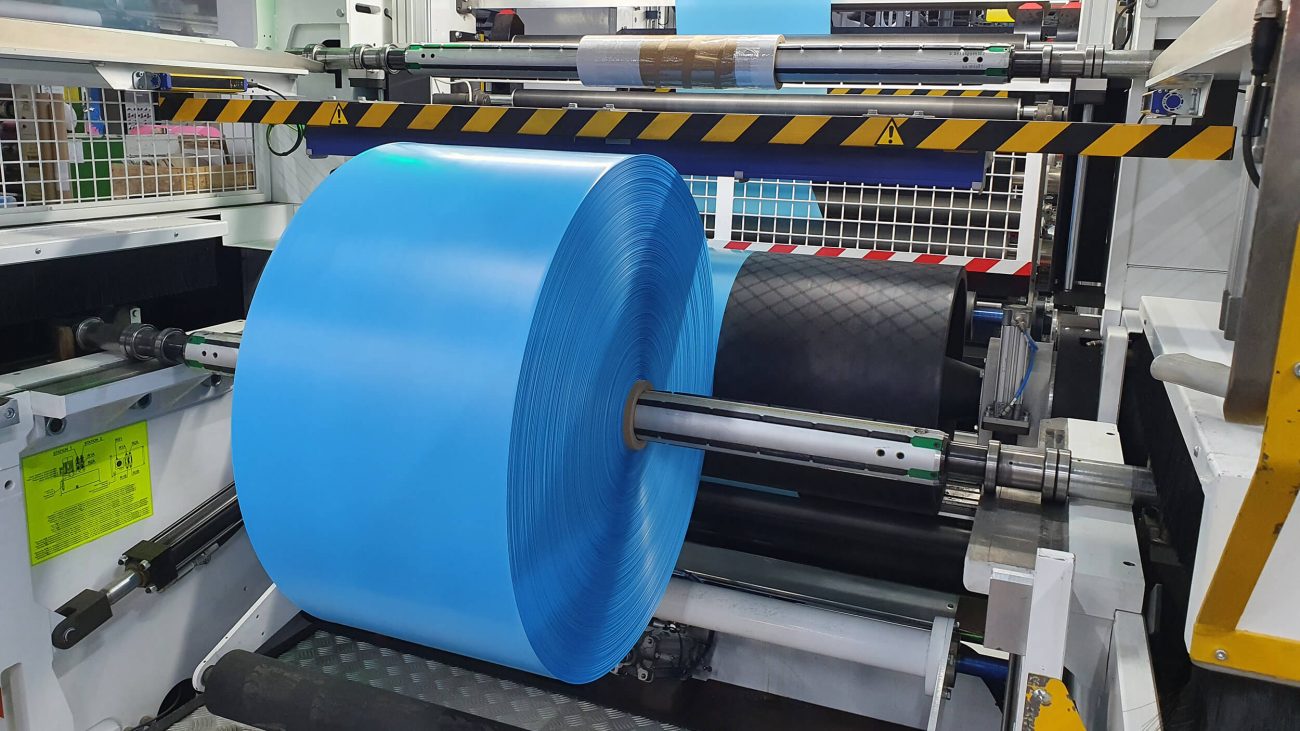

Over 6000 tonnes of polyethylene every year go through our 7 single and multi-layer production lines. The extrusion process is fully-automated and continuously controlled to ensure compliance with your requirements specification.

Our state-of-the-art equipment enables us to:

We specialise in plastic and industrial packaging and offer a wide range of products aimed at the following markets:

Thanks to our 60 years of experience, we understand perfectly your business needs and requirements and therefore we are able to tailor packaging solutions to your needs, market and processes.

We will provide you with personal advice tailored to your individual requirements in terms of product, quality and cost:

By choosing Colly & Martin as your supplier, you choose a trusted partner located in Haute-Loire.

We are a dedicated team of 40 people committed to optimising our state-of-the-art facilities in order to ensure excellent quality product and customer relationship.

We are certified according to:

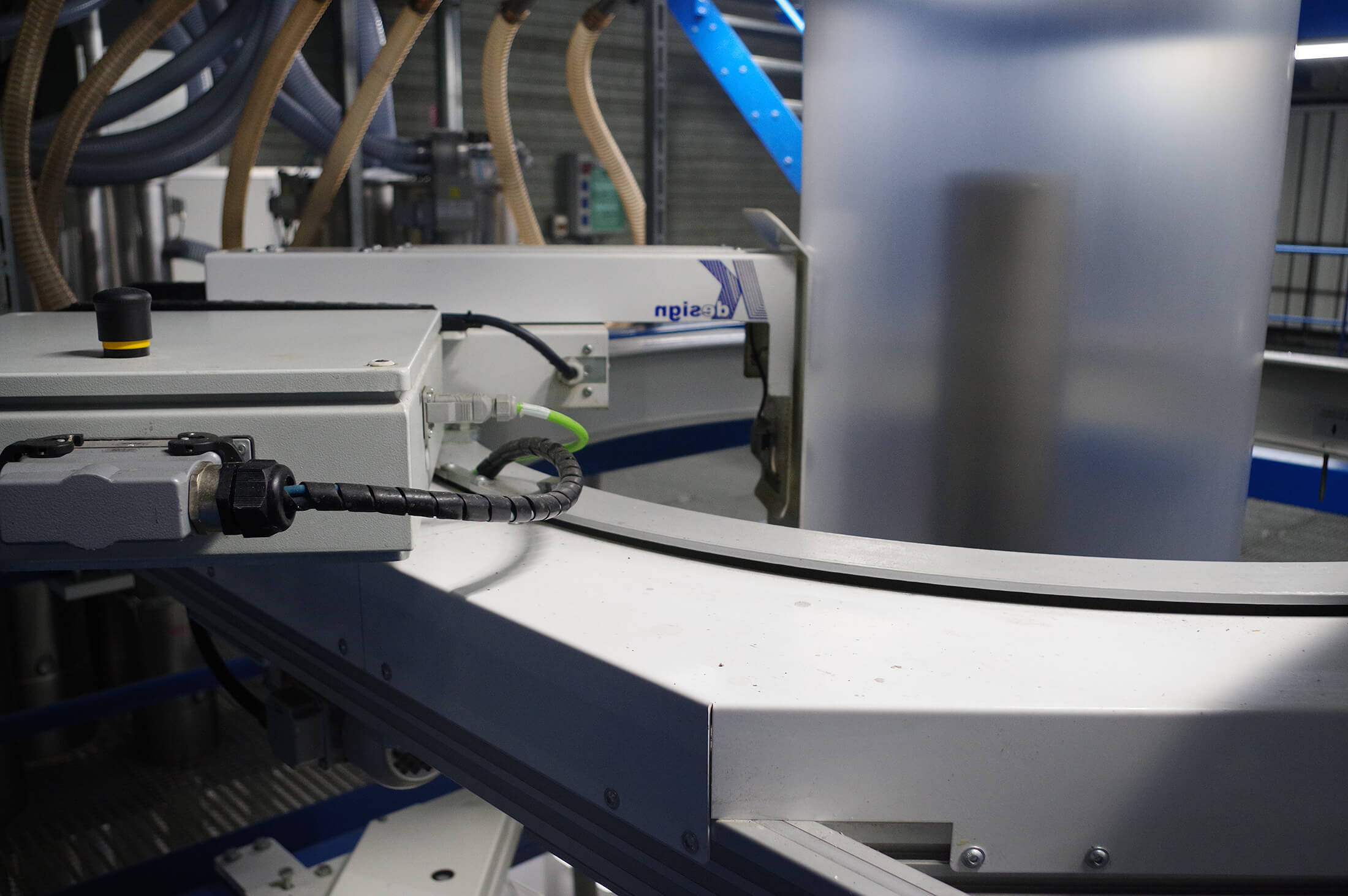

Colly & Martin has 7 single- and co-extrusion lines, two of which renewed in 2018

This automated raw material feeding system is the first in Europe. It ensures traceability, reliability and limits manual handling. It also allows for faster and safer changes in production reducing the potential for material branching errors.

The measuring and regulation devices we use operate on the principle of capacitive measurement and ensure optimum flatness of the surface through continuous real-time control of the profil

for technical products: slippery/non slippery, two-coloured, UV protected… (up to 5 elements per layer)

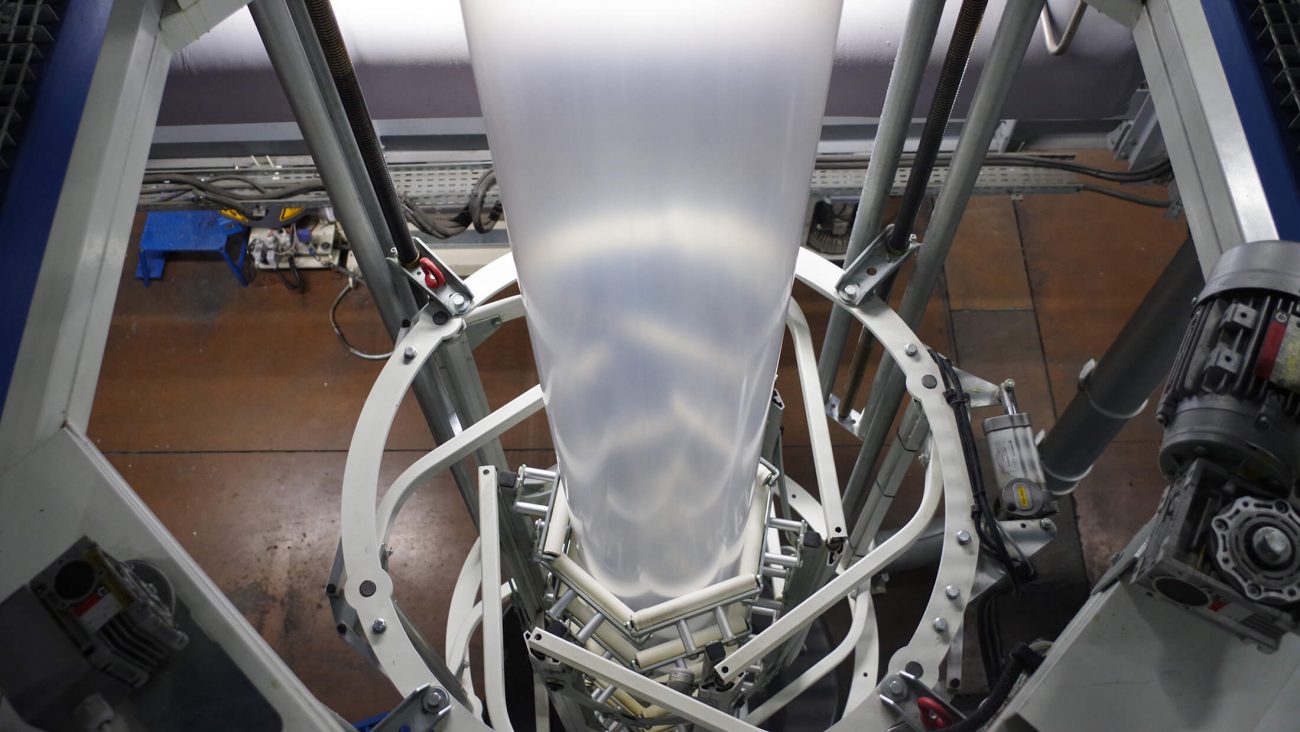

Blow-film extrusion is the process for the production of plastic films and layflat tubing. The raw material (polyethylene) is extruded through an annular die head in the centre of which air is blown. The half perimeter of the plastic tube formed corresponds to the width of the layflat tube. We are equipped to manufacture films and layflat tubes of various colour, thickness and size.